CARTONING MACHINE AND FOOD PACKAGING

Cartoning machine is one of the most implemented and installed packaging machines in the food industry. In accordance with their pattern and flow of operation, cartoners are defined into a wide range of categories.

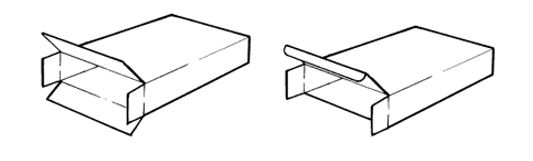

End-Load Cartoner

The machine carton magazine is loaded with flat blanks. The machine’s rotary erector selects a blank on demand and erects it into the moving flight chains. The carton flaps are spread and passed by the product load area ready for the carton to be filled automatically. The carton is then automatically folded, sealed and ejected through driven outfeed belts.

The standard machine is a modular design and is available in a number of different formats to suit a range of applications. The unit is available in Glue or Tuck closure and 6″, 9″, 12″ and 15″ pitch depending on the sizes of the cartons to be run.

Static Bed infeed Option

The static bed automatic infeed is normally selected for use with single items or multiple tray of flowrapped products. The static bed system offers a large space for the product to be loaded into making the transfer of the product to the machine much less critical. It helps reduce changeover times and offers a very compact footprint.

Bucket Infeed Option

The bucket infeed is selected for products that are unstable or delicate. The bucket is designed to carry the product to the prepared carton and offer extra stability and control of the product on transfer to the carton. Multiple layered and sheet products can be compressed on entry to the carton to ensure smooth loading.

It should be noted that there are restrictions on certain combinations of sizes. The size range of the machine is also dependent on the infeed system employed. Additional sizes that are not accommodated in the standard range can be catered for subject to modification

Most Commonly Used Packaging Machine for Food

Cartoning machine is the prevailing secondary packaging machine used in the food industry. From pizza, to muesli and cereal for breakfast, all most every kind of foods we have each day comes in carton boxes. The European Commission has also published several food safety standards for packaging and processing process. Now that food industry is everywhere in our daily life, it is essential to know how to define and evaluate the food safety level of a cartoning machine to avoid legal issues.

Vertical Cartoning Machine

On vertical cartoning machines, the container is taken care of through the machine in an upward position and the item is embedded physically or consequently, most frequently from the highest point of the machine. Vertical cartoning machines are reasonable for bundling “exposed” items that can or should be provided by gravity, and which are sold by weight or volume. Models incorporate rice, dry pasta, and so forth.

Vertical cartoning machine with intermittent motion, and very compact dimensions, high flexibility, simple and fast size changeover operations with removable carton-holders, no need for tools . Products can be manually loaded from the front of the machine. Optionally it is also possible to install automatic feeding systems.

AN OVERVIEW CARTONER MANUFACTURERS IN THE WORLD

ADCO MANUFACTURING

Founded in 1958, ADCO Manufacturing employs over 120 people and operates out of an 81,000 square foot facility in Sanger, CA. To date, ADCO Manufacturing has shipped over 3,600 machines worldwide – a success that CEO Kate King attributes to this family owned corporations’ commitment to quality, value, and world class customer service. ADCO offers a complete line of hand and auto load cartoners, top load carton formers & closers, wrap-around sleevers, custom machinery, and now robotics and corrugated tray formers & case packers.

DOUGLAS

Douglas Machine Inc. is a recognized leader in paperboard, corrugated and shrink-film packaging solutions. Core competencies are cartoners, case packers, tray packers, and shrink-wrappers. Many patented and patent-pending technologies are used in the manufacture of your equipment with many patents in various stages of the patent application process.

We are an employee-owned, market-focused company supported by a continuing cross-functional customer visit program and a significant commitment to research and development. These innovative business tactics enable us to understand and meet your ever-increasing business needs. Today Douglas Machine has over 7,000 machines installed in 30 countries.

CARIBA

For over 30 years now CARIBA has represented the benchmark for anyone looking for an extremely flexible automatic machines manufacturer offering highly customised solutions.

Over this time, CARIBA has developed an outstanding expertise in design and is able to provide technologically advanced solutions in a number of packaging sectors and for a wide range of packaged products: pharmaceuticals, cosmetics, food, household and cleaning products, consumer electronics and small metal parts.

Today, CARIBA’s range of forming, closing and cartoning machines, incorporated into complete packaging lines, represents the ideal solution for companies aiming at high production flexibility with low depreciation costs.

SERPA PACKAGING

Serpa Packaging Solutions is a dynamic manufacturer of high-quality vertical and horizontal balcony cartoners, side load and top load balcony case packers, and tray packers. We also provide complete line integration and validation services, shrink bundlers and palletizers. Serpa has sold almost 1000 machines throughout the United States and across the world.

MAXIMIZE UPTIME

If up time is your primary focus, Serpa Packaging is your company of choice. Our machines are engineered for three shift per day operation with rugged frames and proven technology. Every one of our machines is designed with maintenance in mind. We use outboard belt drives and build the machines with maximum access to every maintenance area.

FOCUSED ON SERVICE

Serpa Packaging Solutions was founded by Fernando Serpa in 1981 after many years of experience as a machine service technician. We vow to provide the best service in the industry. We have grown steadily over the past 25+ years with a strong focus on building low-maintenance, user-friendly, durable machines due to Fernando’s background.

COMPLETE END OF LINE PACKAGING SOLUTIONS

Our mission is to become the end of line packaging company of choice by providing the most advanced technology and by establishing long-term, trusting relationships with our customers. We want to be your single source for complete end of line packaging solutions.

COMPLETE VALIDATED LINES

We have a major presence in the pharmaceutical, medical device, personal care, cosmetics and nutraceutical industries. We have engineered complete validated lines for the most demanding customers. Serpa Packaging Solutions has the ability to package anything that goes into a carton or case.

FIVE ESSENTIAL STEPS FOR CHOOSING A CARTONING MACHINE

There is no “right or wrong” method to choosing the appropriate cartoning machine for a given application. In fact, it should often be a somewhat personal method that yields results that you are comfortable with and can justify from a business point of view. However, I have seen many people struggle with this task over the years, often confused by the large array of choices worldwide as well as some ambiguous advice.

The five step guideline that I am suggesting is as a result of watching people go through their decision-makingca process for more than 25 years. This step by step process is from observations of the cartoning machinery sales experience in over eighty countries for the full array of products to be packaged in cartons, including food household goods, pharmaceutical, industrial, automotive, chemical, and so forth. I believe these steps equally apply to both small and large companies, although the decision-making process and technical resources can often be very different. There is no question that other steps or factors can be added to this guide. However, I felt that since this buying (or leasing) decision path is still somewhat of a personal or company philosophical process, keeping the steps limited to “the basics”, without bias to a particular market or strategy, would help it apply as an introductory approach on a broader scale. If you are involved, or going to be involved soon, in deciding what type of cartoning machine to acquire, I suggest that you and/or your buying team include the following five steps.

STEP 1 – ESTABLISH A BUDGET FOR THE PROJECT

The fact is that you and your buying team know your process better than anyone. The desire to purchase (or lease) a cartoning machine is typically driven by the desire to more efficiently package your product, improve ergonomics (eliminate repetitive motion injuries), and/or improve the aesthetics of your package. You must analyze your present process as well as your goals to improve this process. In some cases, it may be nothing more than to make your carton more tamper resistant while, in other cases, it may be to eliminate as much labor in the process as practical.

This decision to automate your cartoning operation should be done with the objective of also minimizing the material cost of the package. Justifying the cost of the machine is a one-time event while it is reducing the cost of material that will truly pay dividends over the long run.

Don’t be easily swayed with the idea that a project’s goal should be to eliminate all labor on the line. The reality is that you should know the true cost of your labor on the line and, in most cases, the cost of the special engineering element to eliminate all labor turns out not to be justifiable, either from a price and/or a technological point of view. Consider that in many cases, the use of labor on the line, providing that it is properly planned for ergonomically, can actually enhance the performance of the line. Vision systems and other methods of quality control are readily available as add-ons to the packaging line. However, there are certain products and processes that still make human inspection, especially on lower volume lines, more practical.

In any event, whether you are seeking a semi-automatic carton sealer or a totally automated product handling and cartoning system, knowing your present costs and your objectives for return on investment can easily set the stage for a “budget range” going into a project that should prove economically feasible.

STEP 2 –THE PRODUCT SHOULD HELP DETERMINE THE CHOICE

Before you look at possible suppliers, level of feasible automation, etc., it iscritically fundamental that you consider the nature of the product first. In many cases, the nature of the product will actually dictate the type of cartoning machine necessary to do the job. Therefore, by employing this first step, you could very well eliminate several critical path choices up front that will keep the task focused and more efficient.

For example, if the product is free flowing, granular in nature and is to be filled directly into carton (e.g. detergent powder), or several loose pieces (e.g. 25 count cough drops), limit your search strictly to vertical style cartoning equipment. Asmost cartoning machine models available on the market are horizontal, this will immediately eliminate the majority of machine and supplier company choices. Simply jumping in and looking at all suppliers in the market would have been time consuming and distracting.There are also product characteristics that may lend toward a tray forming and cover closing machinery system decision or wraparound concepts such as full wrap, tray pack, or wraparound sleeving.

If the nature of the product is applicable to loading into the carton horizontally, I would suggest that the critical path decisions then go in that direction, even if the product could theoretically be loaded either horizontally or vertically. This is where some of my colleagues may disagree (especially those that specialize in vertical, tray forming, or wraparound cartoning machinery). It is a fact that the majority of cartoning machinery sales and cartoning machine models available are horizontal in nature. I believe this is because, as a general rule, horizontal cartoners can do the job at a lower cost, smaller footprint, more flexibility, and lend to more affordably adding product-handling automation.

STEP 3 – WHAT SPEED IS TRULY REQUIRED?

As simple as this question may seem, I have seen many customers struggle with it over the years. One of the most popular answers to this question is, “What speed can you give me?” This critical step is where I have seen many make the wrong purchase decision, either by under-buying or over-killing the project. Answer this question as accurately as possible as the second critical step behind machine style will work wonders for immediately eliminating all of the choices that are not relevant for this project. In considering the answer to this question, first determine whether the cartoning operation will be on-line or off-line production.

ON-LINE PACKAGING

If it is on-line (i.e. packaging the product as it is made), the formula becomes much easier. Simply calculate the maximum rate that it is possible to make the product divided by the number of products that go into each carton. To that number, you can certainly either add some factor to “surge capability” or potential to increase the rate over time via new processes or product making technology.

OFF-LINE PACKAGING

When considering off-line speed requirements (i.e. packing from pre-existing inventory), objectively consider the daily, weekly, or monthly quotas necessary to ship out the door. Make sure that when you then calculate this into the cartons per minute required, you use a realistic number with regard to days per week that you will really pack as well as a realistic number for “true” hours per day, rather then just dividing by eight for a one shift operation.

Regardless of whether you need to carton your product on or off line, be careful. When making this critical path decision, avoid letting your ego get in the way. I have seen many make the mistake in both directions. When making volume estimates, be realistic of the current picture and the probability of increasing the current volume over the next few years. Some overestimate their needs and end up with a cartoning machine that is larger and more expensive than what is really necessary to do the job. If higher volumes are really needed, don’t be quick to sacrifice those capabilities for price. I have witnessed many that have let price rather than volume determine their final decision and end up with a machine that falls far short of their true needs. In other words, don’t fool yourself into buying the economy of a KIA if you really need, expect, and can maintain the performance of a Lamborghini.

STEP 4 – KNOW YOUR COMPANY’S CAPABILITIES AND NEEDS

A step often overlooked in the process is a self-assessment of your company’s true capabilities when it comes to technical expertise and ability to maintain a cartoning machine. The type of equipment that you investigate must, in your best opinion, match your company’s technical prowess. Unless you have, or plan on making an investment in qualified technical staff, acquiring a machine that incorporates a high technical content could prove disastrous. Match the machine to your capabilities. Buying a machine with servo technology and not having any staff capable of working with it spells trouble. Build a list of factors that are both important qualifications and match your company’s skill sets.

Perhaps the best way to help you determine if a machine matches your staff’s skill set is to do a reference check during the supplier investigation phase (step 5) of the process. If you are a small family business, do not limit your reference to a visit or phone call to a large multinational. Getting additional feedback from a large company is fine, but you really need to talk to a company of comparable size and skill level to determine if this equipment is something that will perform and be manageable for you. In my opinion, talking to someone in the same industry is not as important as talking to someone of comparable size and skill sets.

Beyond the basics of budget, machine type and speed, typical factors that can also play a part in your decision may be specific needs such as delivery time (for time sensitive market roll out projects), changeover time between sizes (especially for short run environments), parts availability (if located in a remote area), and service capabilities (if weak on in-house ability).

STEP 5 – RESEARCH AND DIFFERENTIATE YOUR SUPPLIER OPTIONS

Now that you have narrowed your search to a specific style of machine as well as the speed requirement, it is time to analyze what is available in the market. You have established a clear enough road map to go out and look at your viable cartoning machine options. Many ask, “Now that I know what I need, where do I start?”

Here are just a few suggestions:

- Trade shows

- PMMI directory

- Internet searches (i.e. packexpo.com)

- Machinery buying guides

- Advice of machinery representatives that have successfully helped you source other types of equipment in the past

- Advice of your industry acquaintances and peers

Unless your application is extremely unusual, we should be able to easy find anywhere from three to six alternatives that fit somewhere in your general budget guidelines. Now it is time to differentiate them by their attributes. Most machinery suppliers have a particular niche that helps set them apart. It is your job to ferret which attribute makes you feel most comfortable in making your decision. Some examples would be as follows: One may seemingly have more experience with your type of product than the others; Another may have geographical proximity to your plant, which does make visits and building a relationship a bit easier; Yet a third may position their product as cutting edge and your staff prefers, and is well equipped, to deal with and want the latest technology; While another may take a more simplistic approach to size changeovers, which may appeal to those without highly trained technical support in house; There are some that can offer a higher level of integration and automation, offering to automate your process further up and downstream on the packaging line.

The ultimate goal is to decide on a supplier that you are not only comfortable working with, but also one that can offer you the most “bang for your buck” for your particular needs, budget, and capabilities.