Packaging for the food industry by iXAPACK GLOBAL

2024-04-04

iXAPACK GLOBAL is a French company specialized in the design and manufacture of end-of-line equipment, ultrasonic cutting, weighing, labeling and packaging machines. Founded 50 years ago, the company offers automation solutions for packaging both in the French market and for export. Among these solutions, iXAPACK GLOBAL provides wrapping machines, cartoners, case packers and banding machines.

Cartoning and boxing solutions

Packaging processes are one of the problems for companies in the food and cosmetic sectors. The automation of production lines makes it possible to increase productivity and reduce production costs, while at the same time reducing labor needs, which are increasingly difficult to find for user companies.

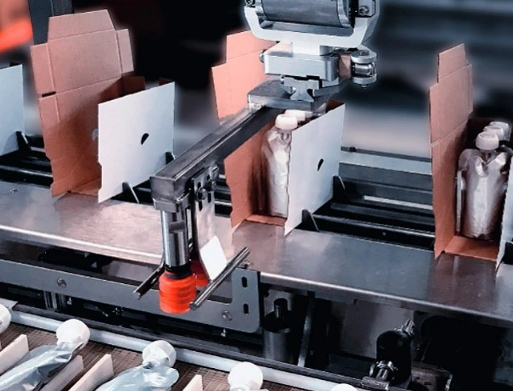

To help its customers in this area, iXAPACK GLOBAL offers two types of equipment for cartoning and packaging products: a Top Load cartoner and a case packer.

Its operation is as follows. First, a polyarticulated robot collects the dies in the warehouse and deposits them between the machine banks. Next, one or more tripod robots pick up and place the products into the boxes (using a pick-and-place process). After this operation, the boxes will be advanced under a gantry, which applies glue to the flaps to seal them.

As for the case packer, its operation is the same. The difference between the two machines is that the Cartoner works continuously to pick and place the products, while the case packer works alternately.

As for the case packer, its operation is the same. The difference between the two machines is that the Cartoner works continuously to pick and place the products, while the case packer works alternately.

These machines are capable of managing multi-formats of both packaging and products. Thus, they stand out not only for their production flexibility, but also for the additional tools made available to customers to expand their functionalities. This is the case, in particular, of the tablet and the on-board camera system, which allow the machine elements to be monitored as close as possible to the affected areas, as well as to record the operation of the machine and identify the cause of any breakdown. in real time.

Furthermore, another end-of-line solution manufactured by the French company is equipment for applying strips, with upper or lower gluing of the containers depending on the type of product being processed.

Upstream of these solutions, IXAPACK GLOBAL proposes packaging equipment, with its Flowpacks machines for the horizontal packaging of products (biscuits or fresh products, for the AFSA version of the equipment) or through its X-Folds wrapping machines.

Palletizing processes can be installed, completing the end-of-line solutions, for automated management of the flows of boxes and cases, at the exit of the Cartoner and Case Packer.

This packaging solution will be exhibited at the Hispack show in Barcelona, from May 7 to 10, at stand F161 in pavilion 3.