Schubert develops innovative robot-assisted packaging line for candy manufacturer

2023-10-14

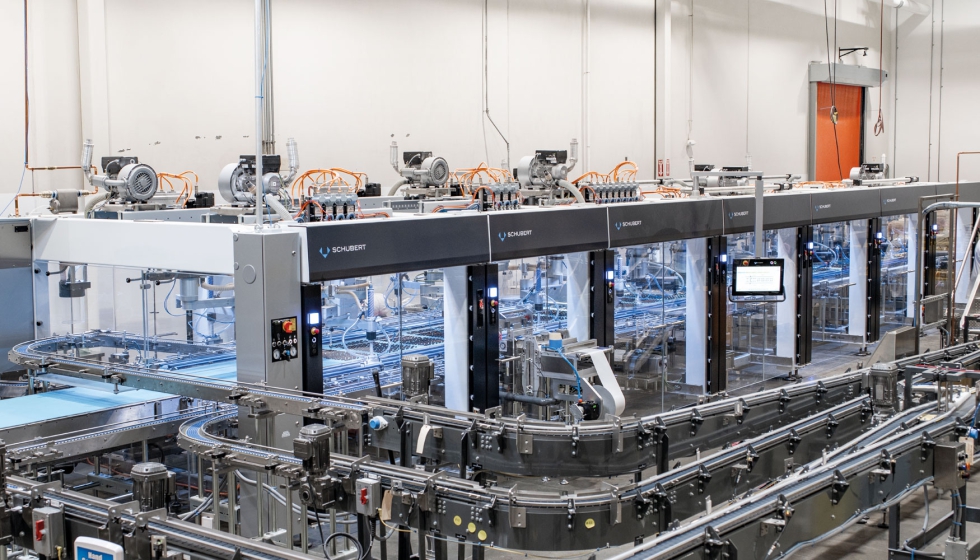

Since 2015, Schubert also has a subsidiary in Charlotte, North Carolina. With a robot-assisted packaging line designed for the leading US candy manufacturer, ‘ Sweet Candy Company ‘, the team located on the American east coast has once again proven that customers on the other side of the Atlantic can also trust on Schubert’s high consulting competence and innovative spirit. The particularity of the new solution: the number of products per packaging can be adjusted while production is in progress.

A Schubert F4 robot places Sweet Candy Company chocolate bars filled with different fruit gelatin in a box.

The solution: packaging by weight using a Pick and Place machine

At Sweet Candy Company, Schubert experts initially encountered a semi-automatic packaging line that only processed around 50% of the products, the remaining part had to be packed by hand. So that the candy manufacturer could achieve the necessary increase in production efficiency, Schubert opted for a fully automatic Picker picking line with 16 F4 robots and the vision system; a highly efficient visual quality control system developed entirely by Schubert. In order to adjust the number of chocolate bars, between 32 and 34 per box, according to needs, Schubert also modified the packaging design. The new packaging houses two layers of product between which a waxed paper is placed. The trick to greater flexibility: with the new packaging, the bottom layer contains a fixed number of chocolate bars, while the top layer can be spontaneously adjusted by adding or decreasing 1 product during the ongoing production process. This only requires manual entry into the machine’s operator interface. In this way, Sweet’s can now also package chocolate bars fully automatically based on weight.

Unique in its kind: The “spontaneous” adjustment of the number of products,

which can be carried out during production by manually entering the desired change on the control panel.

Fully automatic packaging instead of manual work

Sweet Candy Company is more than satisfied with the fully automated global solution that consists of a Pickerline with integrated F4 robots, with the new packaging design that incorporates a waxed paper separator between the two layers of product and with the “spontaneous” adjustment of the number of products per box based on weight. Rick Kay, CEO of Sweet Candy Company, enthusiastically describes working together with Schubert: “The decision in favor of Schubert was obvious, and I don’t regret it one bit. “Our expectations have been completely met.”