The latest in flexible packaging printing and multi-layer laminations

2022-12-27

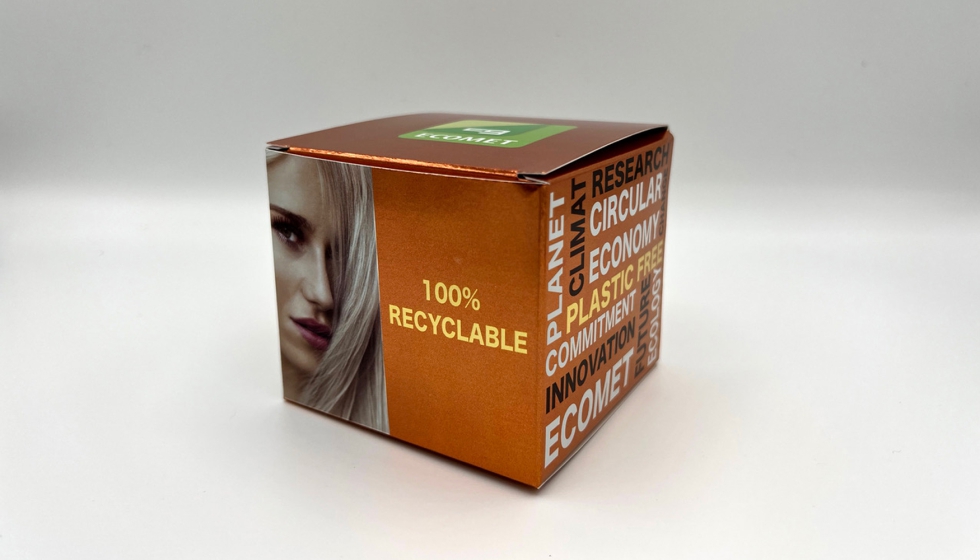

For Cellografica Gerosa S.A, “sustainability is a very important value in our society where companies must do our part to collaborate and help the future generations of our planet”. “In our company we are oriented to this need and that is why we have promoted the Ecomet”.

For a long time the company has laminated paper and cardboard with metallized polyester or aluminum, until the question arose of how they could obtain a metallic finish with similar characteristics, but without plastic film in order to obtain a final complex one hundred percent recyclable as paper. “That’s where the idea of the metallized transfer came from, which Cellografica Gerosa has baptized as Ecomet (of an ecological material according to what the planet demands of us),” they indicate.

Ecomet carton box

The Ecomet system consists of a lamination of a metallized film where the metallized part of the film is transferred to the surface of the paper or cardboard by means of an adhesive.

Subsequently, we remove the polyester sheet leaving only the metallized on the cardboard or paper. The plastic film is rewound at the same time to be used again as a base to metallize it and return at the end of the process.

It has been a few years until we have been able to see Ecomet as a reality on the market, with many internal tests, customer in-house tests to control the adhesion of the metal to the paper/ cardboard surface, the subsequent printing, embossing, embossing, slits, etc…

“During 2022 we have noticed an important demand for sustainable materials from different customers, different markets and we have been able to see the demand for our new technology take off,” they point out. “The satisfaction of seeing our Ecomet material in cosmetic boxes, perfumery, parapharmacy, food and cases in general, makes us see this product as one of the most interesting in our product portfolio and of more travel. If someone were to ask us today how we see the future for this type of materials, undoubtedly we would have in mind recyclable materials to help in the circular economy”.

One of the main achievements in the field of recyclability and also environmental is that the metal layer transferred to the surface of the paper / cardboard is so thin that when the cardboard is recycled in what is called the spinning and shredding process, it disappears completely, favoring the reuse of this paper or cardboard as one hundred percent paper material.

“Different tests in several laboratories and universities have certified this important achievement for us: Ecomet is a 100% recyclable material like cardboard or paper,” they add. Among the environmental advantages of replacing a mixed cardboard and metallized polyester container with a cardboard one-Ecomet highlights that its better eco-design allows the container to be made of a single material instead of a mixed bilayer, which minimizes the generation of company waste. It facilitates the recycling of the materials (second life) since there are no mixtures of them.

Plastic film demaculation process

It increases the sustainability index of the company and its integration towards a circular economy (efficient economy in the use of resources) and finally, it helps to increase the Corporate social responsibility of the Company (CSR) by introducing measures that reduce the environmental impact of its activity.

“In the pyramid of the Ecological Hierarchy (where we have from least to most favorable): Disposal, energy recovery, recycling, reuse, minimization and finally, more favorable, prevention, cardboard with metallized polyester would be in the least favorable option as energy recovery and Ecomet would be almost at the tip of the pyramid as minimization,” they conclude.

Cellografica Gerosa

In 1993, the Gerosa Group and Vescoflex merged their expertise in the field of printing and lamination. After more than 25 years of collaboration, Cellografica Gerosa S.A. currently has 20,000 m2 for the production and management of gravure prints and laminates of different types of materials for flexible packaging. The materials manufactured are mainly: polyaminates for wine and sparkling wine capsules, materials for ice cream corneas, labels with aluminum, paper and three-layer and up to 4-layer laminates, as well as cardboard complexes with plastic films or metallized finishes (Ecomet).