What are Case Packers and What are the Benefits of Corrugated Cardboard Boxes?

2023-08-31

Case packers serve a crucial role in packaging operations by automating the process of packing products into corrugated boxes or cases. This blog aims to explore the concept of case packaging, shed light on the characteristics of corrugated box cases, discuss various types of case packers, and emphasize the advantages of utilizing corrugated cardboard cases. Drawing from credible industry sources and studies, we will provide an in-depth analysis of the importance and benefits associated with case packaging.

Case Packaging as an Essential Packaging Solution: Packaging is instrumental in safeguarding products throughout their journey from producer to consumer. Case packaging, particularly with corrugated cardboard cases, has gained widespread popularity due to its unparalleled durability, versatility, and cost-effectiveness (TAPPI, 2017). The utilization of case packers, which streamline and automate the packing process, offers increased efficiency, reduced labor costs, and stringent quality control.

Corrugated Cardboard Cases: A Comprehensive Overview: Corrugated cardboard cases consist of three layers of paper: an inner liner, an outer liner, and a fluted medium positioned between them (Doyon, 2018). This construction imparts remarkable strength, rigidity, and protection to the packaged product. The fluted medium acts as a shock absorber, cushioning the contents and minimizing the risk of damage during handling, transportation, and storage.

What are case packers?

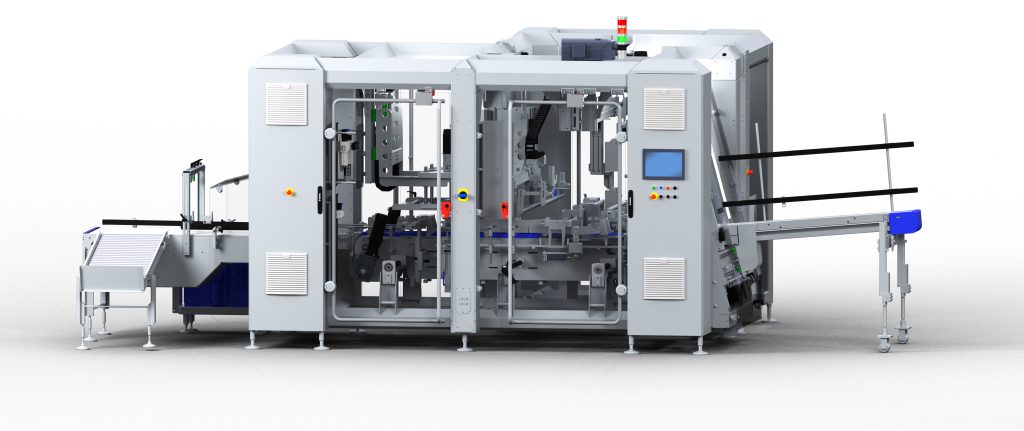

Case packers are machines used in packaging operations to automate the process of packing products into cases or boxes. These machines are designed to efficiently and accurately load products into containers, ensuring consistency and speed in the packaging process.

Case packers come in various types and configurations to accommodate different packaging needs. They can handle a wide range of products, including bottles, cans, cartons, pouches, and more. The primary goal of case packers is to automate the packing process, reducing the need for manual labor and increasing efficiency.

Typically, case packers are equipped with mechanisms that pick up products from a conveyor belt or an upstream machine and place them into pre-formed cases or boxes. Some case packers can also form cases from flat sheets of cardboard or corrugated material before loading the products.

What are the different types of case packers?

- Vertical Case Packers: These case packers load products into cases from the top, making them particularly suitable for fragile or delicate items. Vertical packing minimizes the potential for impact damage during the packing process, ensuring the integrity of the packaged products while maintaining operational efficiency and speed (Gheysens et al., 2020).

- Horizontal Case Packers: In contrast to vertical case packers, horizontal case packers load products into cases from the side in a horizontal orientation. These highly versatile machines can accommodate a wide range of product shapes and sizes, making them ideal for high-speed packing operations (Shi et al., 2019). The versatility in product orientation ensures efficient utilization of space within the case.

- Robotic Case Packers: Equipped with articulated robotic arms, robotic case packers offer unparalleled flexibility. These machines can be programmed to handle various product types and execute complex packing patterns with precision (Trinomic, 2021). Robotic case packers excel in delivering adaptability, speed, and accuracy in packing operations.

Case packers play a crucial role in optimizing packaging operations by ensuring consistent and efficient packing processes. They offer benefits such as increased production speed, reduced labor costs, improved product integrity, and overall operational efficiency.

What are Corrugated Cardboard and Corrugated Cases?

Corrugated cardboard is a versatile and widely used packaging material composed of three layers of paper: an inner liner, an outer liner, and a fluted medium positioned between them. This construction gives corrugated cardboard its characteristic rigidity, strength, and cushioning properties.

The inner liner and outer liner, also known as the facings, provide protection and stability to the cardboard. The fluted medium, which consists of a series of ridges and valleys, acts as a cushioning layer and adds strength to the cardboard. The flutes also create air pockets that enhance the cardboard’s resistance to impacts and shocks during handling, transportation, and storage.

Corrugated cases, often referred to as corrugated boxes, are containers made from corrugated cardboard. They are commonly used for packaging and transporting various products, ranging from small items to large shipments. Corrugated cases are designed to provide protection, support, and secure containment for the products they hold.

Corrugated cases offer several advantages as packaging solutions. They are lightweight, easy to handle, and cost-effective. The cushioning effect of the fluted medium in corrugated cases helps absorb shocks and prevent damage to the contents inside. Additionally, corrugated cases can be customized with printing, labeling, and structural modifications to meet specific product requirements and branding needs.

Corrugated cardboard and corrugated cases are highly versatile and widely used in numerous industries, including food and beverage, e-commerce, electronics, pharmaceuticals, and more. Their popularity stems from their durability, recyclability, cost-effectiveness, and ability to provide effective protection for products during their journey from producer to consumer.

What are the different types of corrugated cardboard?

Corrugated cardboard comes in various types, each designed for different packaging applications and requirements. The main factors that differentiate these types are the number of layers (plies) and the flute size. Here are the most common types of corrugated cardboard:

- Single-Wall Corrugated Cardboard: Single-wall corrugated cardboard, also known as “single-face,” consists of one flute sandwiched between two flat liners. This type of corrugated cardboard is flexible, lightweight, and often used for low-cost packaging applications.

- Double-Wall Corrugated Cardboard: Double-wall corrugated cardboard has two flutes separated by three layers of flat liners. This type offers enhanced strength and rigidity compared to single-wall cardboard. It is commonly used for heavier or more delicate products that require additional protection during shipping and handling.

- Triple-Wall Corrugated Cardboard: Triple-wall corrugated cardboard consists of three flutes and four flat liner layers. This type provides even greater strength and durability, making it suitable for extremely heavy or fragile products.

- Micro-Flute Corrugated Cardboard: Micro-flute corrugated cardboard contains smaller flutes and thinner flat liners compared to standard corrugated cardboard. It offers excellent printability and is often used for retail packaging, displays, and point-of-purchase (POP) applications.

Each type of corrugated cardboard has its own strengths and applications. Choosing the appropriate type mainly depends on factors such as the weight and fragility of the packaged product, transportation needs, and desired level of protection. Manufacturers and packaging experts can provide guidance in selecting the correct type of corrugated cardboard for specific packaging requirements.

What are the Advantages of Case Packaging with Corrugated Cardboard Cases:

- Strength and Protection: Corrugated cardboard cases provide exceptional strength and protection to the packaged products. The fluted medium acts as a cushioning layer, absorbing shocks and minimizing the risk of damage during transit and handling (TAPPI, 2017). This ensures that the products remain intact and reach end consumers in optimal condition.

- Sustainability: Corrugated cardboard is a sustainable packaging material derived from renewable resources and is easily recyclable. It contributes to waste reduction, reduced carbon emissions, and the promotion of circular economy principles (FPA, 2018). By opting for corrugated cardboard cases, companies display their commitment to environmental stewardship by offering sustainable packaging options to consumers.

- Customizability and Branding: Corrugated cardboard cases can be easily customized to suit specific product requirements and branding needs. Whether incorporating product information or adding handles for convenience, customization allows for enhanced product presentation and improved consumer experience (Doyon, 2018). Customized packaging promotes brand recognition and differentiation in a competitive market.

- Cost-effectiveness: Utilizing corrugated cardboard cases proves to be cost-effective compared to other packaging materials such as plastic or wood. The abundance and competitive pricing of corrugated cardboard make it an economical choice for businesses across various industries (Shi et al., 2019). The cost-efficiency of corrugated cardboard cases enables companies of all sizes to benefit from a reliable and sustainable packaging solution.

What are the best materials to make corrugated cardboard boxes?

The best materials to make corrugated cardboard boxes depend on the specific requirements of the packaging application. Generally, corrugated cardboard boxes are composed of three essential components: the inner liner, the outer liner, and the fluted medium. Here are the primary materials used for each component:

- Inner Liner: The inner liner, also known as the facing, is the layer of cardboard that comes in direct contact with the product. It provides stability, protection, and a smooth surface for printing. The inner liner is typically made of Kraft paper or recycled paperboard. Kraft paper is a high-strength paper made from wood pulp, while recycled paperboard is made from used paper materials.

- Outer Liner: The outer liner is the layer of cardboard that forms the exterior surface of the box. It offers strength and durability to the overall structure. Like the inner liner, the outer liner is also commonly made from Kraft paper or recycled paperboard.

- Fluted Medium: The fluted medium is the layer sandwiched between the inner and outer liners. It provides cushioning, rigidity, and structural strength to the corrugated cardboard. The fluted medium consists of a series of parallel flutes or ridges that create air pockets. The most common material used for the fluted medium is called corrugating medium, which is typically made from a combination of wood pulp fibers.

It’s worth noting that the quality and performance of corrugated cardboard boxes can vary depending on the specific grades and types of materials used. These materials may also undergo additional treatments or enhancements, such as water resistance coatings or flame-retardant additives, to meet specific packaging requirements.

Ultimately, the selection of materials for corrugated cardboard boxes should be based on factors such as the desired strength, durability, environmental considerations, and specific packaging needs for a given application. Packaging experts and manufacturers can provide guidance on the best materials and configurations for different box requirements.

Are Corrugated Cardboard Boxes Sustainable?

Corrugated cardboard boxes are considered a sustainable packaging option for several reasons. They are made from a renewable and recyclable material—paper derived from trees. Moreover, the production of corrugated cardboard boxes involves low energy consumption and generates fewer greenhouse gas emissions compared to many other packaging materials.

Here are some reasons why corrugated cardboard boxes are considered sustainable:

- Renewable Material: Cardboard is made from paper, which comes from trees—a renewable resource. Responsible forestry practices, such as replanting trees and promoting sustainable forest management, help ensure a continuous supply of raw materials.

- Recyclability: Corrugated cardboard is highly recyclable. After use, cardboard boxes can be collected, sorted, and recycled into new paper products. Recycling cardboard helps conserve resources, reduces the need for virgin materials, and minimizes waste going to landfills.

- Biodegradability: If corrugated cardboard boxes do end up in landfills or other environments, they break down naturally over time. Cardboard is biodegradable, meaning it can decompose without leaving harmful residues.

- Lightweight: Corrugated cardboard is lightweight, which means it requires less energy for transportation. Lighter packaging reduces fuel consumption and associated carbon emissions during shipping.

- Life Cycle Assessment: The production of corrugated cardboard boxes typically has a lower environmental impact compared to alternative packaging materials. Life cycle assessments (LCAs) have shown that this packaging option performs favorably in areas such as energy use, greenhouse gas emissions, and water consumption.

While corrugated cardboard boxes have many sustainable attributes, it’s important to address any potential environmental impacts associated with their production and disposal. For instance, the use of certain coatings, inks, or adhesives on cardboard boxes can affect their recyclability or compostability. Additionally, proper recycling infrastructure, consumer education, and responsible waste management practices are necessary to maximize the sustainability potential of corrugated cardboard packaging.

Where can I buy some reliable case packer machines?

There are several reputable manufacturers and suppliers that offer reliable case packer machines. Here are some popular options:

- Bosch Packaging Technology: Bosch is a leading provider of packaging equipment, including case packer machines. They offer a range of models to meet various packaging needs, from low to high-speed operations.

- Krones: Krones specializes in packaging, filling, and labeling solutions. They offer case packer machines suitable for various industries, including food and beverage, pharmaceuticals, and personal care.

- Schneider Packaging Equipment Co., Inc.: Schneider Packaging Equipment is known for its robust and efficient case packer machines. They offer customized solutions and have a strong reputation for quality and reliability.

- Hartness (Part of the ITW Family): Hartness offers cutting-edge case packer machines for industries such as beverage, food, household, and personal care. Their equipment is designed to maximize efficiency and minimize downtime.

- A-B-C Packaging Machine Corporation: A-B-C Packaging is a well-established manufacturer of case packer machines. They offer a wide range of options, including fully automatic, semi-automatic, and robotic case packing systems.

- Brenton Engineering: Brenton Engineering is a leading provider of end-of-line packaging solutions, including case packer machines. They offer innovative and customizable solutions for various packaging requirements.

While these companies are known for their reliable case packer machines, it’s essential to evaluate your specific needs, production requirements, and budget before making a purchase. Consultation with packaging equipment specialists and conducting thorough research will help you find the most suitable and reliable case packer machine for your business. Additionally, trade shows, industry publications, and online marketplaces can be valuable resources for finding and comparing different machine options and suppliers.